Did you know that using plastic corrugated sheeting can reduce environmental waste? The answer is yes, but it must be ensured that the raw materials of the product are of high quality. The plastic corrugated sheets produced by Huiyuan can not only be reused as much as possible but can also be recycled at the end of the product’s useful life – secondary use.

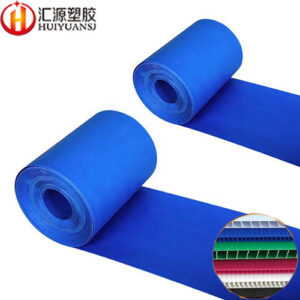

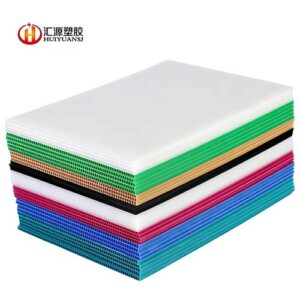

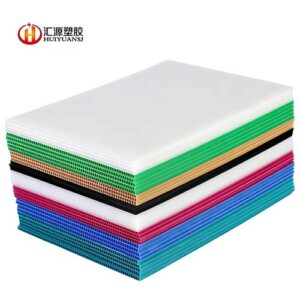

In different countries, Plastic corrugated Sheeting is also known as Coroplast, Corflute, Correx, Danpla, Infraboard, Impraboard, and Flutedboard.

Because the raw material of PP corrugated boards is PP (polypropylene). Polypropylene is a natural semi-crystalline thermoplastic that is resistant to chemicals, oil, water, and UV light at ambient temperatures. That’s why polypropylene can survive harsh weather conditions. The best feature of PP is its resistance to various organic solvents and acids and bases, which makes it an ideal material for different outdoor uses. In addition, high-quality polypropylene is non-toxic and tasteless. People can completely recycle and reuse. Therefore, more and more industries choose this environmentally friendly material.

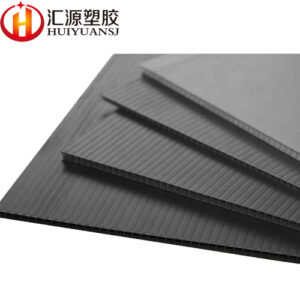

At present, the H-type structure is the most common pp hollow board in the market, mainly used for lining and small pp corrugated boxes. Common thickness is between 2-7mm. Usually, the gram weight is 300-1800g (choose the gram weight and thickness according to the actual design needs).

There are single honeycomb and double honeycomb panels on the market, and their comprehensive properties such as compressive strength and bending strength are relatively superior.

For the inner lining: The thickness is generally about 5mm, and the more commonly used weight is 1200g.

For the large plastic gaylord box: the thickness is more than 10mm (about 12mm), and the gram weight is 3000-3500 grams.

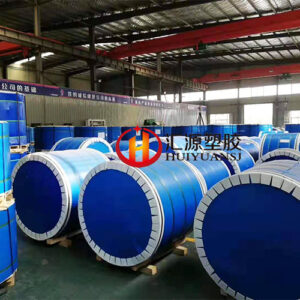

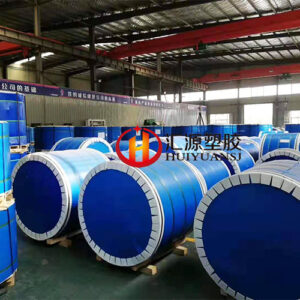

Suzhou Huiyuan Plastic Products Co., Ltd is committed to providing customers with more professional products, more competitive prices, and more comprehensive services. Using our actions to make the greatest efforts for the environmental protection of the earth, is Huiyuan Plastics’ commitment. We have professional knowledge, an excellent and experienced design team, and high-quality customer service staff to provide customers with more convenient and professional one-stop overall solutions.

If you want to buy high-quality plastic corrugated sheeting, contact us now!