Correx board, also known as fluted polypropylene board, has become a staple material in signage, displays, and promotional campaigns. Lightweight, durable, water-resistant, and cost-effective, Correx boards are particularly popular for outdoor signage, election campaign signs, retail promotions, and industrial applications. If you are considering getting customized Correx boards printed directly from a manufacturer, this guide will walk you through every step of the process—from understanding the material to final delivery.

What Is Correx Board?

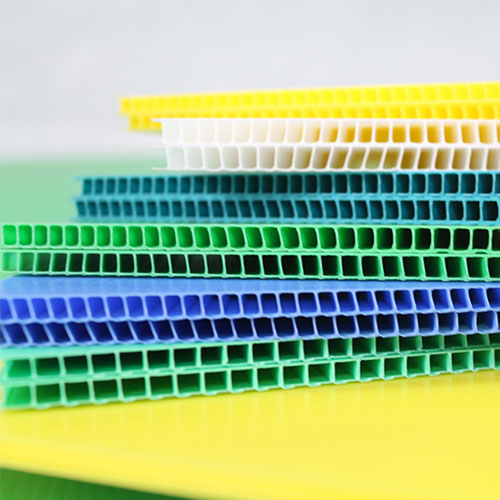

Before diving into printing, it is essential to understand what Correx board is. Correx is made from polypropylene sheets with a fluted structure, which gives it strength while keeping it lightweight. This material is flexible yet sturdy, making it suitable for both indoor and outdoor use. Unlike cardboard, Correx boards are waterproof and resistant to tearing, which ensures longevity even under harsh weather conditions.

Correx boards are available in various thicknesses, typically ranging from 2mm to 10mm. The most common thickness for signage is 4mm, providing the perfect balance between rigidity and portability. Colors also vary, with standard options including white, black, and colored sheets that can be printed on directly or coated with vinyl for additional design options.

Applications of Printed Correx Boards

Printed Correx boards have a wide range of applications:

- Outdoor Advertising: Lightweight boards are easy to transport and mount, ideal for banners, shop signs, and event promotions.

- Political Campaigns: Correx boards are widely used for election signage because of their durability and ease of mass production.

- Retail Promotions: POP (Point of Purchase) displays, shelf signage, and promotional boards often use printed Correx for cost-effective marketing.

- Construction and Industrial Uses: Safety notices, directional signage, and temporary site boards are often made from Correx because it withstands outdoor conditions.

Understanding your intended application is crucial when deciding on the thickness, color, and print method.

Choosing the Right Manufacturer

Printing Correx boards is a specialized process that requires precise handling. Choosing the right manufacturer can make a huge difference in quality, cost, and turnaround time. Here are some factors to consider:

- Experience: Look for manufacturers with proven experience in producing printed Correx boards. Years of expertise ensure they understand material behavior and printing limitations.

- Printing Technology: The best manufacturers offer multiple printing options, including digital, screen, and UV printing. This flexibility allows you to choose a method that fits your design and budget.

- Customization Options: Some manufacturers provide additional services like die-cutting, lamination, or mounting, which can enhance your project’s final outcome.

- Quality Assurance: Ensure the manufacturer tests boards for durability, print quality, and color accuracy. This reduces the risk of fading or damage during use.

- Delivery Capabilities: Reliable shipping and logistics are essential, especially for bulk orders. Confirm that the manufacturer can handle your required quantity and deliver on time.

Preparing Your Design for Printing

High-quality printing starts with proper design preparation. Here’s what to keep in mind:

- File Format: Most manufacturers accept vector files such as AI, EPS, or PDF for the best print quality. Raster images (like JPEG or PNG) can be used, but ensure the resolution is at least 300 DPI.

- Color Mode: Printing usually uses CMYK color mode. Designs created in RGB may look different when printed. Always convert to CMYK before submitting your file.

- Bleed and Margins: Correx boards often require a small bleed area (3–5mm) to ensure the print goes edge-to-edge without white borders. Keep critical text away from the edges to prevent cutting errors.

- Font and Readability: Large, bold fonts are preferable for outdoor boards that need to be legible from a distance. Avoid overly intricate fonts that may lose clarity when printed.

Selecting the Right Printing Method

The printing method greatly affects the final look, cost, and durability of your Correx boards. Common options include:

- Screen Printing: Ideal for bulk orders with solid colors. Screen printing provides vibrant, opaque colors but is less suitable for complex designs or gradients.

- Digital Printing: Perfect for detailed designs, photographs, or small runs. Digital printing allows for full-color graphics with high resolution.

- UV Printing: Offers excellent durability, especially for outdoor use. UV ink cures instantly on the board surface, creating a weather-resistant finish.

The choice depends on your budget, quantity, and the complexity of your design.

Ordering and Production Process

Once your design is ready and a manufacturer is selected, the ordering process generally follows these steps:

- Request a Quote: Provide board size, thickness, quantity, and print specifications to get an accurate quote.

- Sample Approval: Manufacturers usually produce a sample board for approval. This allows you to check color, print quality, and material feel before committing to a full order.

- Production: After sample approval, full-scale production begins. Depending on the order size, production can take anywhere from a few days to a couple of weeks.

- Quality Check: Reputable manufacturers inspect each board for printing defects, color consistency, and material integrity before shipping.

Finishing Options

Depending on your project, finishing touches can enhance the functionality and appearance of your printed Correx boards.

- Die-Cutting: Create custom shapes or cutouts for unique displays.

- Lamination: Adds a protective layer against scratches, UV light, and moisture.

- Mounting: Attach boards to stakes, frames, or adhesive backings for easy installation.

Shipping and Handling

Printed Correx boards are lightweight but can be bulky in large quantities. Proper packaging prevents bending, scratching, or damage during transit. Many manufacturers use flat packaging with protective layers or stackable crates for larger orders.

When receiving your boards, inspect each batch for defects or color discrepancies. If issues are found, notify the manufacturer immediately to resolve any problems.

Conclusion

Printing Correx boards from a manufacturer can be a straightforward process if you understand the material, choose the right printing method, and work with a reliable manufacturer. From preparing your design to final delivery, each step impacts the quality and effectiveness of your signage.

Whether you need boards for outdoor advertising, retail promotions, or industrial applications, investing in high-quality printed Correx boards ensures durability, visual appeal, and long-term value. By following the guidelines above, you can confidently order custom printed Correx boards that meet your exact specifications and leave a lasting impression.

For businesses, organizations, or individuals looking to create standout signage, working directly with a professional Correx board manufacturer not only saves time and money but also guarantees a product that performs as intended.